Quality Control and Inspection Services

We supply documentation upon demand for all quality functions including First Article, in Process, SPC, Final Inspection, and supplier certifications.

- Our Quality Rating from 2008 to 2022 is 99.95%

- Our PPM (Parts Per Million) from 2008 to 2022 is 270 with 100,965,579 parts shipped.

Inspection Capabilities

Quality Control

Our inspection department provides experienced personnel and inspection equipment, necessary to satisfy our customers’ ever-tightening quality requirements.

We supply documentation upon demand for all quality functions including: First Article, in Process, SPC, Final Inspection, and supplier certifications. ISO 9001 Certified.

Part Size

We can assemble components in all sizes and shapes. Talk to our engineers about your design.

Part Size

We can assemble components in all sizes and shapes. Talk to our engineers about your design.

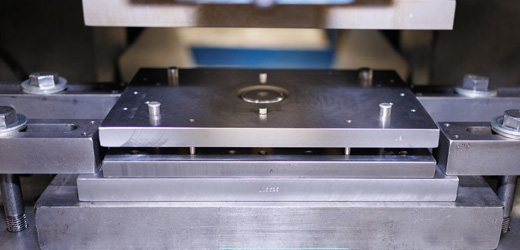

Automation

We have both automated and manual machines to complete the inspection of your parts.

Secondary Operations

We have CNC machining capabilities to handle all secondary drilling, countersinking, counter boring, reaming, and detailed machining. We also do tapping, welding, spot welding, deburring, and assembling.

Materials

We manufacture parts from a wide range of materials including most metals, plastics, synthetics, rubber, and cloth to mention a few.

Minimum Order

We can accommodate designs for prototypes as well as high volume production runs.

Our Certifications

ISO 9001 specifies requirements for a quality management system when an organization:

- needs to demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements

- aims to enhance customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements.

Nadcap is an industry-managed approach to conformity assessment that brings together technical experts from both Industry and Government to establish requirements for accreditation, accredit Suppliers and define operational program requirements. This results in a standardized approach to quality assurance and a reduction in redundant auditing throughout the aerospace industry because Prime contractors, Suppliers and Government representatives have joined forces to develop a program that:

- Establishes stringent industry consensus standards that satisfy the requirements of all participants

- Replaces routine auditing of Suppliers with one approved through a consensus decision-making process of members from the user community

- Conducts more in-depth, technically superior critical process audits

- Improves Supplier quality throughout the industry through stringent requirements

- Reduces costs through improved standardization

- Utilizes technically expert auditors to assure process familiarity

Trusted By Leading Businesses

Klesk Metal Stamping

Experience Precision

At The Highest Quality.

From Aerospace to Telecommunications, our expertise ensures unparalleled quality.

Explore Our Services

Metal Stamping

Klesk Metal Stamping Co. is equipped with punch presses ranging in tonnage from 5 to 100 tons.

EDM Wire & Hole Drilling

Klesk Metal Stamping Co. has EDM production since 1977. We have wire, conventional, and small hole drilling EDM.

Engineering Services

The engineers at Klesk Metal Stamping Co. specialize in early product involvement and helping our customers design.

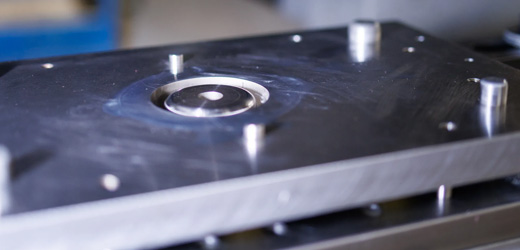

Tooling Design & Fabrication

To meet the needs of our customers we have a modern tool room with a staff of highly trained tool and die makers.

Assembly Fabrication

At Klesk Metal Stamping Co. we assemble both standard and custom-made hardware to our stamped parts.

We Make It Simple To Get Started.

With Klesk Metal Stamping, starting your precision metal project is as easy as 1, 2, 3.

01. Request A Quote

Get a tailored estimate

02. Review With An Expert

We work to understand your needs

03. Get Started

Embark on your precision journey