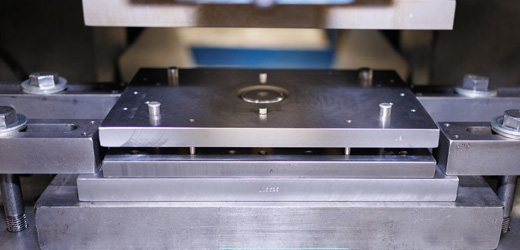

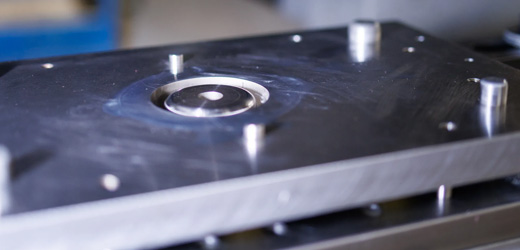

EDM Wire and Hole Drilling

We use our EDM equipment to build our production tooling, build fixtures, do prototypes and to do our development work. Our Precision hole drilling department is capable of drilling holes from 0.004 to 0.125″ in diameter and depths to 9 inches in a production mode. Our traveling Wire EDM features anti-electrolysis (patented) providing protection against corrosion, oxidation, and discoloration on iron, steel, aluminum, and titanium alloys. We specialize in running production quantities with our Wire EDM and EDM small-hole drilling equipment.

EDM Machining Capabilities

Wire Diameters

Our precision hole drilling department is capable of drilling holes from 0.004″ to 0.012″ in diameter and from .008 to .125 diameter electrodes.

The EDM Hole Drilling electrode sizes range from 0.008” to 0.187”

EDM Hole Drilling Capabilities

Our equipment is capable of fabricating holes up to 9″ deep.

X-axis = 12” Y-axis = 8” and Z-axis = 10”

Our EDM Wire Capabilities

X-axis = 19.5” Y-axis = 13.5” Z-axis = 11”, and our machines have 4-axis capabilities

Component Preservation

Our traveling Wire EDM features anti-electrolysis (patented) providing protection against corrosion, oxidation and discoloration on iron, steel, aluminum, and titanium alloys.

Part Size

1/2″ square to 12″ square

Materials

We manufacture parts from a wide range of materials. The EDM process can be used to fabricate components from ALL conductive materials including Tungsten, Platinum, Rhodium, Haynes, Beryllium Copper, Titanium, Tantalum and High Performance Alloys.

Secondary Operations

We have CNC machining capabilities to handle all secondary drilling, countersinking, counter boring, reaming, and detailed machining. We also do tapping, welding, spot welding, deburring, and assembling.

Minimum Order

We can accommodate designs for prototypes as well as high volume production runs.

Trusted By Leading Businesses

Klesk Metal Stamping

Experience Precision

At The Highest Quality.

From Aerospace to Telecommunications, our expertise ensures unparalleled quality.

Explore Our Services

Metal Stamping

Klesk Metal Stamping Co. is equipped with punch presses ranging in tonnage from 5 to 100 tons.

Quality Assurance

Our inspection department provides experienced personnel and modern inspection equipment.

Engineering Services

The engineers at Klesk Metal Stamping Co. specialize in early product involvement and helping our customers design.

Tooling Design & Fabrication

To meet the needs of our customers we have a modern tool room with a staff of highly trained tool and die makers.

Assembly Fabrication

At Klesk Metal Stamping Co. we assemble both standard and custom-made hardware to our stamped parts.

We Make It Simple To Get Started.

With Klesk Metal Stamping, starting your precision metal project is as easy as 1, 2, 3.

01. Request A Quote

Get a tailored estimate

02. Review With An Expert

We work to understand your needs

03. Get Started

Embark on your precision journey