Our Services

01. Metal Stamping

Klesk Metal Stamping Co. is equipped with punch presses ranging in tonnage from 5 to 100 tons.

02. EDM Wire & Hole Drilling

Klesk Metal Stamping Co. has EDM production since 1977. We have wire, conventional, and small hole drilling EDM.

03. Quality Control

Our inspection department provides experienced personnel and modern inspection equipment.

04. Engineering Services

The engineers at Klesk Metal Stamping Co. specialize in early product involvement and helping our customers design.

05. Tooling Design & Fabrication

To meet the needs of our customers we have a modern tool room with a staff of highly trained tool and die makers.

06. Assembly Fabrication

At Klesk Metal Stamping Co. we assemble both standard and custom-made hardware to our stamped parts.

Our work speaks for us

Expert Solutions, Real-World Results

Dive into our impactful case studies and witness precision at its best.

Aerospace Customer

Business Industry

Client's Challenge

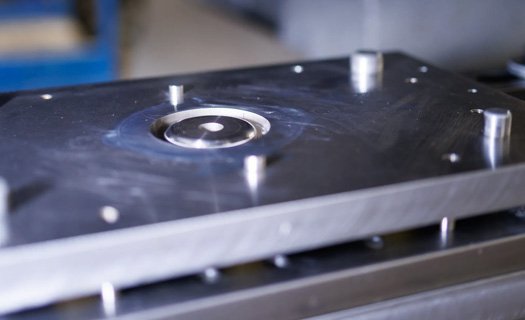

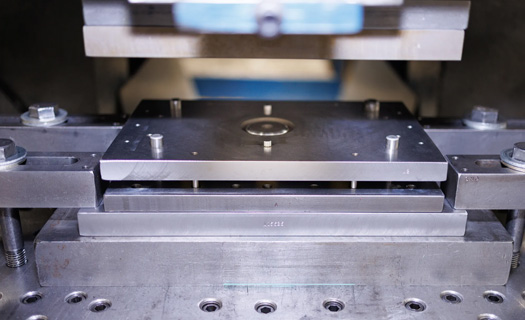

An aerospace customer sought support from Klesk in the design and production of a thin foil part (0.001 inch) made of a specialty metal that is a critical component of an apparatus for the customer’s main vehicles. The aerospace customer approached Klesk with a part to quote where the print callouts were extremely challenging to produce and measure. The part also required passivation, and no vendor would quote due to the extremely thin material of the part.

Detailed Review Of Our Work

Klesk worked with the customer’s engineers to understand their needs as well as the form, fit, and function of the part. A collaborative approach led to Klesk designers building prototype tools and parts that satisfied the customer’s needs. After the tremendous success of the prototypes, Klesk adapted the initial tooling into highly repeatable production-level tooling, and the drawing was updated to a measurable state. To address the passivation challenge, Klesk designed and built fixtures to protect the parts during the passivation process. This creative approach improved lead times, reduced fallout, and strengthened the partnership with the aerospace customer.

Client Case Study #1

Business Industry

Client's Challenge

Detailed Review Of Our Work

Client Case Study #2

We Make It Simple To Get Started.

With Klesk Metal Stamping, starting your precision metal project is as easy as 1, 2, 3.

01. Request A Quote

Get a tailored estimate

02. Review With An Expert

We work to understand your needs

03. Get Started

Embark on your precision journey